Turnkey Analytical Systems

In today’s ever-changing industrial environment, it is essential to conduct precise and timely analysis in order to maximize operations, ensure product quality and meet regulatory requirements. Dipietro Group stands out as a leading systems integrator, specializing in the provision of cutting-edge analytical systems for process analysis.

With over 30 years of experience in the sector, we have developed important references for turnkey E&P projects characterized by a flexible and coherent executive model.

We are highly specialized in the implementation of customized solutions for:

- Industrial process analysis

- Chemical and industrial automation;

- Environmental monitoring and analysis;

- Water and steam analysis;

- FPSO, FLNG, LNG offshore e onshore.

The processes involved in these industries are complex and require continuous monitoring to ensure efficient and safe operations. A fundamental element is the analytical component, which plays an essential role in ensuring the correct execution of processes.

The use of online analysis systems leads to an improvement in the production process, safety and environmental protection; By continuously monitoring critical parameters, our systems can detect potential dangers before they become significant risks.

Our turnkey packages include a wide range of technologies, online analyzers, sensors, data acquisition systems and advanced software solutions. We design and produce complete packages for measuring the physical and chemical properties of liquids and gases. Our solutions are designed based on sample properties, process requirements, EPC/End-user material specifications, sub-suppliers, environmental conditions, to provide a complete package that includes everything needed to a fully functional application.

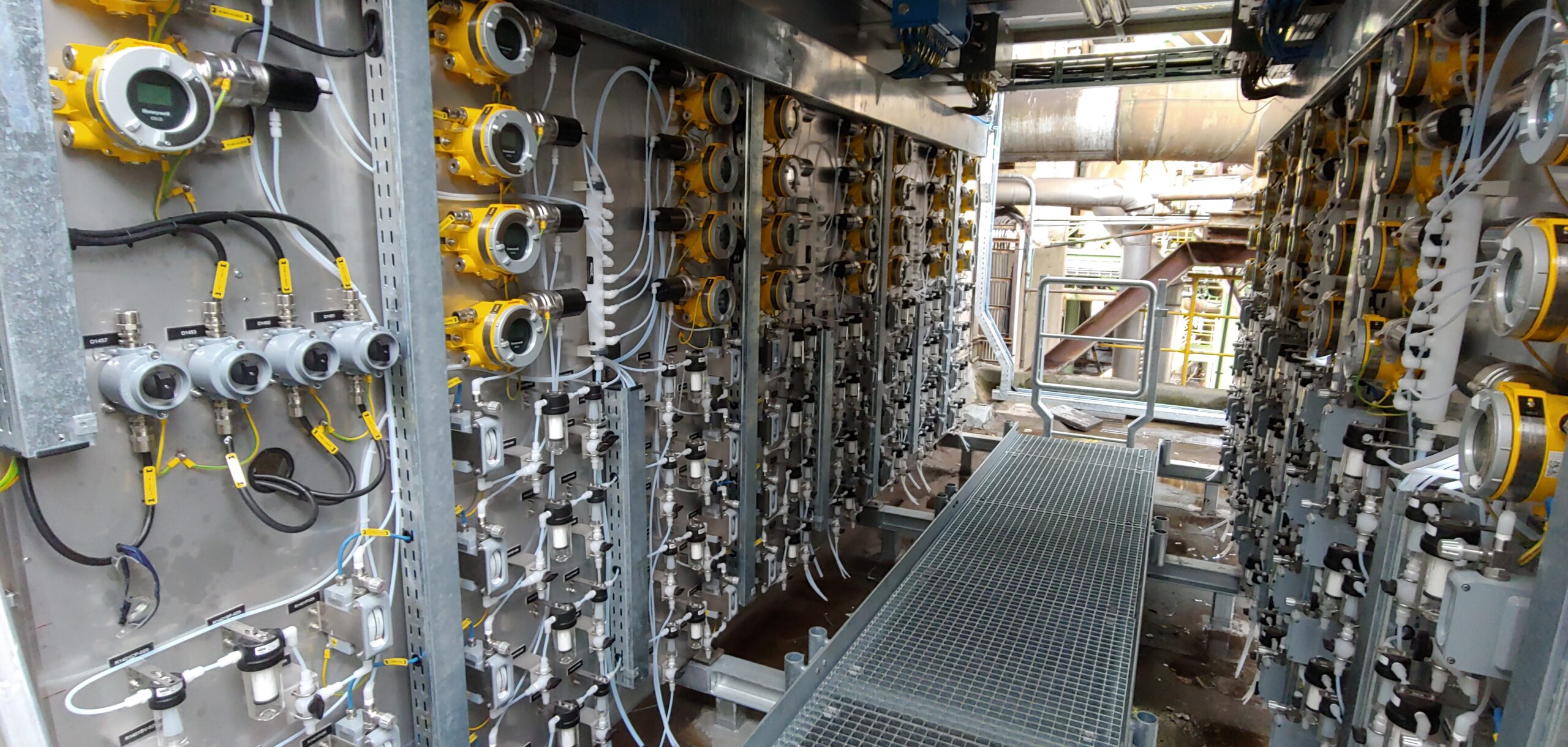

Online Analysis Booths

All our systems can be supplied in a wide range of configurations, including all the sample handling systems needed to ensure the correct functioning of any application:

- Cabin with or without ventilation and pressurization systems;

- Cabinets with or without pressurization systems;

- Cabin open on one side;

- Racks suitable for assembly or with self-supporting system.

Providing high quality solutions is one of our main goals: cabinets and/or cabinets can be made of a wide range of materials, including galvanized steel, stainless steel, glass reinforced plastic, concrete, designed according to NFPA 496, IEC 61285, GOST, ECAS or any other international standard and are always complete with the relevant ATEX and DNV certificates.

Safety and reliability are considerations of the utmost importance in the field of process analysis, in fact, our cabinets guarantee a safe environment from external factors such as atmospheric agents, dust and other contaminants, guaranteeing the correct functioning of the instrumentation inside.

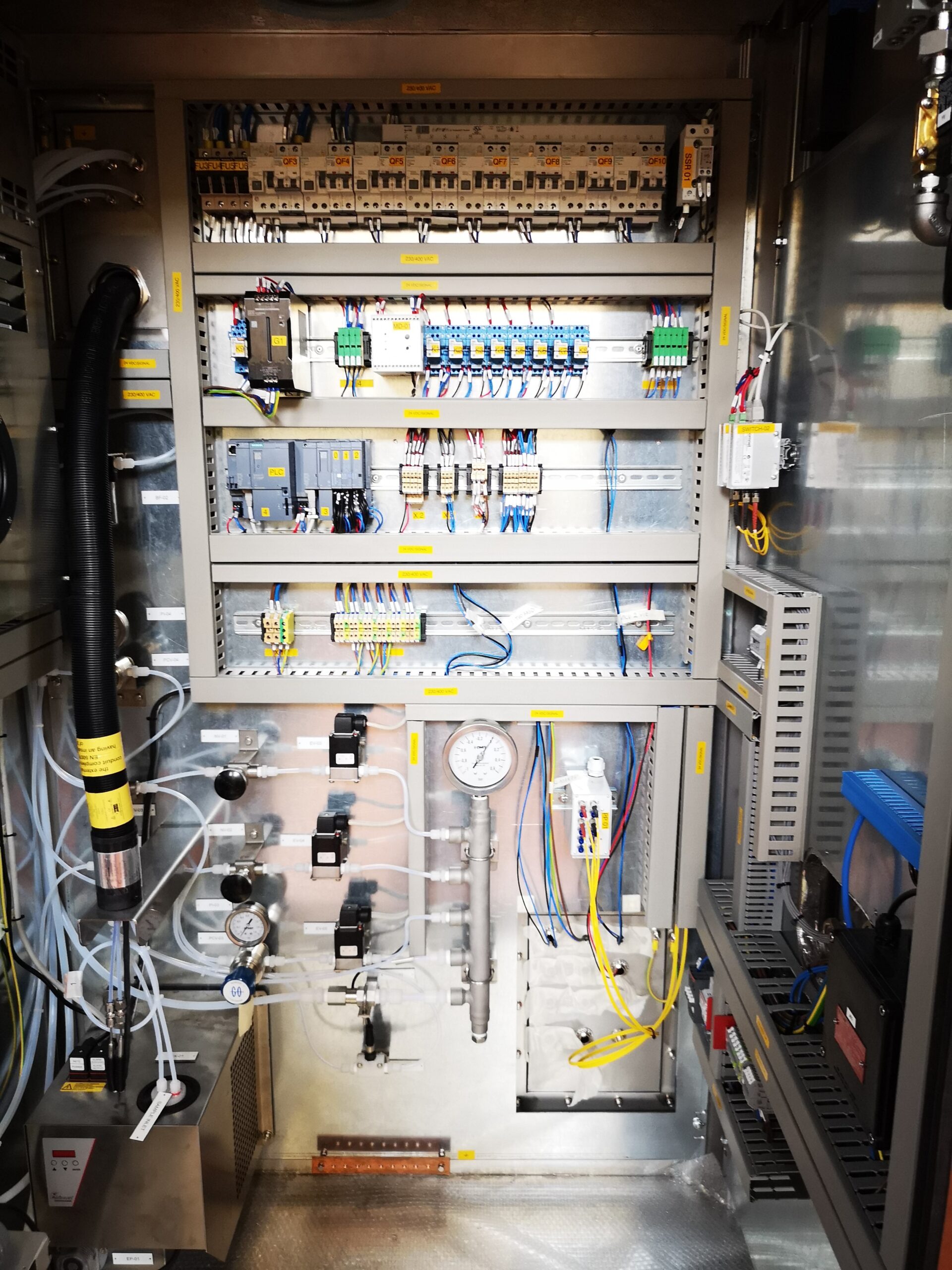

We supply all our systems fully equipped with gas/liquid analyzers and samplers, complete with auxiliary equipment such as sample conditioning systems, power and ventilation systems, components such as pre-installed piping and wiring to connect the application to the process.

HVAC | Heating, Ventilation and Air Conditioning

HVAC (Heating, Ventilation, and Air Conditioning) or HAC (Heating and Cooling) play a fundamental role in analysis cabins, contributing significantly to the precision and reliability of the results obtained. These systems guarantee a controlled and optimal environment inside the cabin, maintaining constant temperature, humidity and ventilation conditions necessary for analysis operations.

Our HVAC/HAC are designed taking into account project requirements and system specifications, guaranteeing stable environmental conditions to ensure the reproducibility and reliability of continuous analysis. Thanks to accurate control of temperature and humidity, our systems help preserve the integrity of the samples and minimize variations that could influence the analysis results.

Furthermore, proper ventilation provided by the HVAC or HAC ensures adequate air circulation within the cabin, minimizing the presence of contaminants and ensuring a safe and comfortable working environment for testing personnel.

SME | Continuous Emission Monitoring Systems

Continuous Emission Monitoring Systems (EMS) play a crucial role in monitoring and managing the environmental impact of industrial activities.

Our offering includes SMEs designed for use in both hazardous and safe areas. Our added value consists in identifying appropriate instruments and analyzers for the specific application, equipped with analytical measurement technologies compliant with the reference standards, such as EN 14181, among others.

Value Proposition

Accuracy and Reliability: Our EMS provide accurate and reliable measurements of gaseous and particular emissions from industrial plants, allowing companies to accurately assess their environmental impact and identify potential areas for improvement.

Regulatory Compliance: Our systems are designed to meet rigorous environmental regulatory standards and allow companies to continuously monitor their emissions to ensure compliance with local, national and international regulations.

Process Optimization: Using the data collected by our systems, companies can analyze the performance of their plants and optimize production processes to maximize energy efficiency, reduce operating costs and minimize overall environmental impact.

SWAS | Steam and Water Analysis Systems

Our SWAS systems are designed to provide accurate, real-time analysis of the chemical/physical characteristics of water, allowing operators to closely monitor water quality and intervene promptly in case of any variations or anomalies. Our solutions are complete with everything necessary for sample collection, conditioning and analysis, and are made according to the international reference standards ASME PTC 19.11, VGB/DGRL and ASTM D5540.

Sampling systems are mainly used in combination with water analysis equipment for chemical parameters such as conductivity, pH, dissolved oxygen, silica, sodium etc.

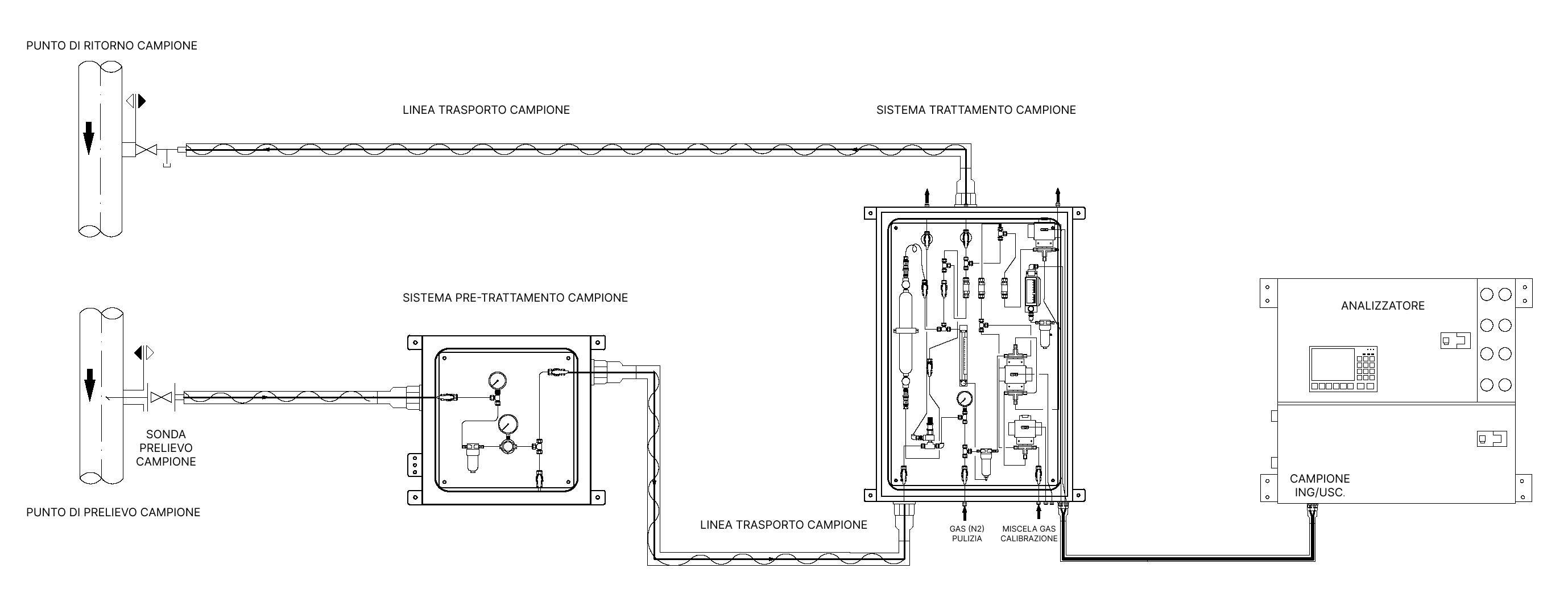

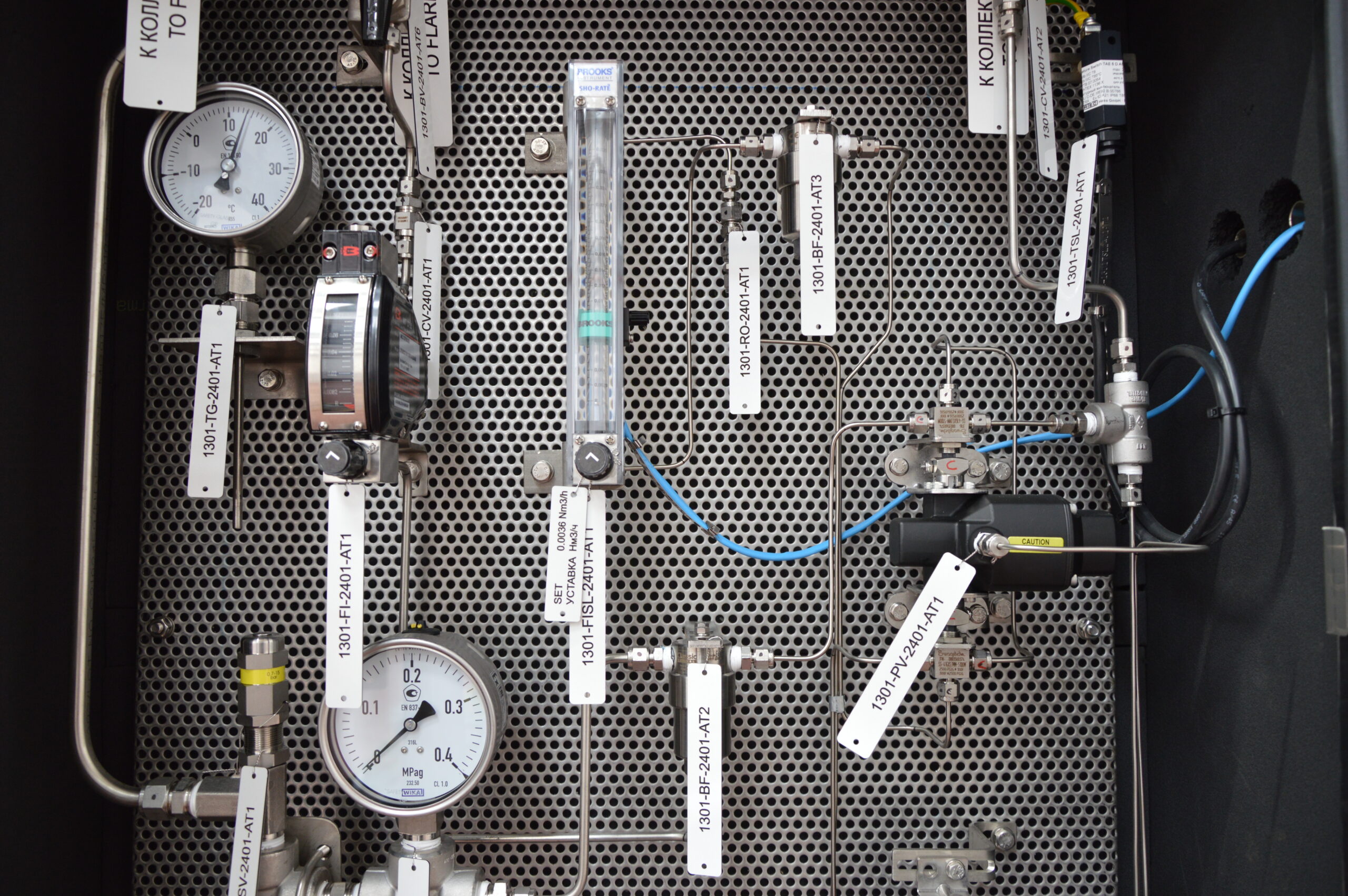

Sampling Systems

With extensive industry experience spanning over 30 years, we can provide comprehensive system design and manufacturing services for sampling (SP), pre-treatment (PSTC) and sample processing (STC). Our goal is to ensure that each solution is perfectly tailored to the specific needs of the process, ensuring that analyzers receive representative samples to obtain accurate and reliable measurements.

Our solutions are designed for use in outdoor industrial environments, compliant with Safe Zone and ATEX safety standards.

The sample processing system is an indispensable part of the analysis loop and must be designed with high quality standards to ensure the correct representativeness of the sample before it reaches the analyzer.

Each system can have different configurations dictated by the sample conditions at the sampling point. Based on these conditions, the system can be simple, for example limited to a pressure reduction, or become more complex if filtering is required for particularly contaminated samples, removal of aggressive substances or condensation harmful to the analyzers. It is important to underline that incorrect design of the sample processing system represents one of the main causes of analyzer failures and high maintenance costs.

The set of equipment necessary for this purpose is called the analysis system and is composed of:

Removable and fixed Sample Collection Probe (SPC):

- Gas probes;

- Liquid probes;

- Probes in special executions for processes with particularly corrosive or condensable samples.

Sample Pre-Treatment System (SPTC):

- Auxiliary pump;

- Pressure regulator;

- Vaporization pressure regulator;

- Cooling or heating system;

- Pressure indicator;

- Temperature indicator.

Sample Treatment System (STC):

- Reduction or increase in blood pressure;

- Filtration from particles and/or condensation;

- Heating or Cooling the temperature;

- Fast-loop flow regulation (kept to a minimum to avoid long sample delay);

- Automatic selection of process streams and calibration;

- Flow regulation to the analyzer;

- Safety Valve (spring return and/or safety valves);

- Sample taken for laboratory and/or integrated sampling system with canister.

Fire & Gas Systems

Our complete solutions for fire & gas detection systems are designed for both on-shore and off-shore applications, using advanced technologies of specific control panels or PLCs.

The detection of gas leaks, smoke and fires today represents an active protection measure against serious accidental events that could cause partial or total damage to industrial plants or sites. This type of detection is also fundamental for the health and safety of people and the protection of the environment. In fact, a carefully designed fire & gas detection system becomes an important ally in the management of industrial risks.

The intervention function is related to other higher systems such as ESD (Emergency Shutdown System) or DCS (Distributed Control System) and is used to transfer confirmation that certain dangerous conditions have been detected. The ESD or DCS normally acquires this intervention and processes the shutdown of the process equipment involved in the hazard, the shutdown of ventilation, the deactivation of rotating equipment or generators, etc.